Two Circuits

First Circuit

Second Circuit

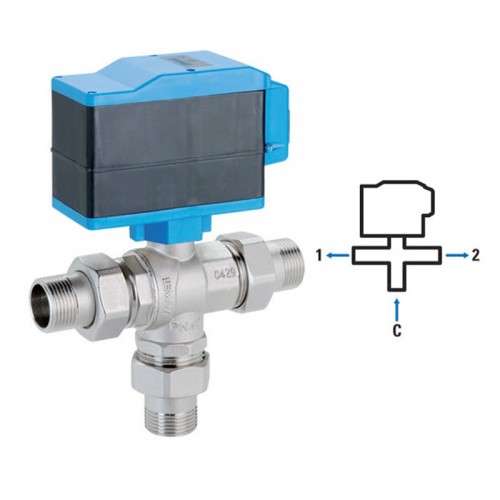

The first open circuit is equipped with a stainless steel expansion vessel, circulator, drain cock and management unit. The second circuit is equipped with a membrane expansion vessel, circulator, drain cock, pressure gauge, 3 bar safety valve and filling valve.

MAXIMUM SECURITY

The CARINCI heating boiler is equipped with 5 internal safety devices, all of which work even in the absence of electricity:

- Open expansion vessel in stainless steel;

- Combustion control valve;

- Double circuit inside the boiler body for each wall;

- Safety valve and expansion tank and membrane in the secondary circuit.

Heating +

DHW pellet tank capacity 35 kg

FROM 50 TO 160 M2 HEATED *

Advantages of the dual circuit system:

- The expansion vessel should no longer be positioned at the highest point in the house;

- Walls or floors must not be broken for the passage of safety tubes;

- Less time for installation;

- Can be installed on the ground floor and also heat the upper floors;

- It is already configured for combination with other heat generators;

- Connecting the Carinci heating boiler to the system has never been so easy.

|

COMBI BOX 160 - Wood / pellets

|

Nominal

|

Reduced

|

|

Burnt power - KW -

|

20.9

|

5.4

|

|

Total power - KW -

|

18.9

|

5.0

|

|

Heating output power (for the room) - KW -

|

1.7

|

0.9

|

|

Power returned to water - KW -

|

17.2

|

4.1

|

|

Performance -% -

|

90.4

|

92.4

|

|

Measured CO (at 13% O2) - mg / mc -

|

69 (0.006%)

|

190 (0.015%)

|

|

Powders measured at 13% O2 - mg-mc -

|

14.8

|

26.2

|

|

Minimum chimney draft requirements - Pa -

|

10 ± 2

|

10 ± 2

|

|

Maximum sanitary water pressure - bar -

|

3

|

3

|

|

Maximum water pressure Heating - bar -

|

two

|

two

|

|

Boiler water content - lt -

|

72

|

72

|

|

Equipment mass - Kg -

|

380

|

380

|

|

Internal combustion diameter (F.) - Ø -

|

180

|

180

|

|

Combustion chamber size (L) - cm -

|

44

|

44

|

|

Combustion chamber size (H) - cm -

|

44

|

44

|

|

Combustion chamber size (P) - cm -

|

39.

|

39.

|

Combustion is the most important element in a fireplace, as all the calorific value of the wood that is not converted into energy is lost in performance.

The innovative CARINCI combustion technique (EXCLUSIVE PATENTING SYSTEM No. 1371478) consists of a simple principle, heating the combustion air before it enters the combustion chamber.

HIGH IGNITION

The CARINCI fireplace stove, thanks to its unique, innovative combustion technique, allows the user to charge it by placing the large wood below, the small one above and lighting the fire above. This rapid ignition technique ensures homogeneous combustion, burning the wood from top to bottom, uniformly and gradually, exploiting maximum fuel efficiency, significantly reducing smoke production and pollutant emissions.

"A.Q.S." SYSTEM

The A.Q.S SYSTEM, designed by Grupo Carinci, allows the collection of hot sanitary water with little fire, at low temperatures (already at 40 ° C) and even with the fire extinguished for at least half a day after shutdown.

BENEFITS

- Easy loading

- Simple ignition

- diffuse flame

- Heating speed

- Wood preheating

- Heating autonomy

- Low pollutant emissions

- With a single load of wood up to 6/8 hours of heating

- Go out with complete freedom and security without having to take care of him

- Easy and quick to clean

MULTI-FUEL BURNER WITH FUEL SUPPLY FROM THE BOTTOM

The innovative Carinci burner technology "Power from the Low" guarantees considerable advantages compared to traditional stoves, which are fed by dropping pellets directly into the flame.

BENEFITS

- Can burn any type of wood pellet, even low quality

- Can also burn other biomass

- Self-leveling burner

- Right amount of primary air

- Secondary air

- Preheated fuel

- Preheated primary and secondary air

- Constant combustion (no fuel falling over the flame)

- Expulsion of ash naturally (not driven by the fan or mechanisms)

- Low daily maintenance for cleaning braziers

- Dual glow plug (reduced ignition times)

AUTOMATIC REVERSAL MOTOR - ANTI-LOCK - EXTREMELY QUIET

Auto-reverse motor safety: the CARINCI COMBI thermal imager geared motor is equipped with a safety control with a reverse-feed feed screw, which reverses the direction of travel automatically for about one turn when greater resistance is detected in transporting the product. fuel. thus the fuel is blocked to resume normal operation and thus preventing boiler blockage and any breakdown of the fuel supply system.

ELECTRONIC IGNITION WITH DOUBLE SERIES CANDLE

Electronic ignition with double spark plugs guarantees fast, safe and constant ignition over time.

MANAGEMENT SOFTWARE

The control unit allows the ignition to be programmed automatically at any time.

.jpg)