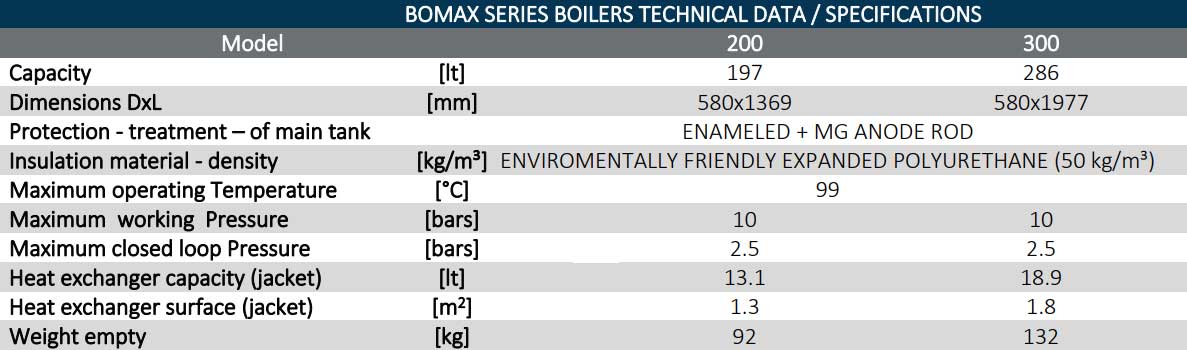

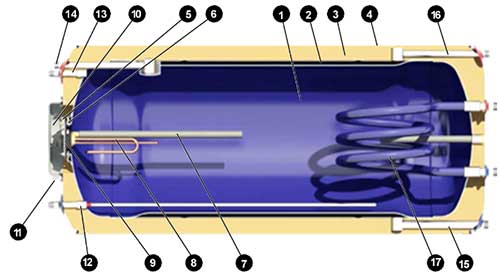

1. Water storage tank: Consists of cold rolled steel, 3mm thick with double internal layer of enamel, processed at 860° c, according to DIN 4753 Standard.

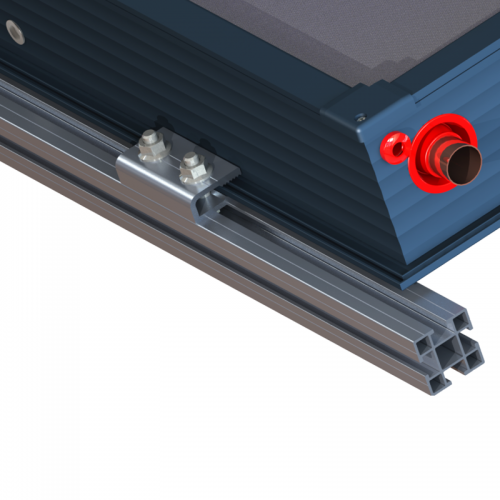

2. Double jacket heat exchanger: Consisting of cold rolled steel, 1.5mm thick, for the function of the closed loop circuit. The jacket is properly formed for resistance to contractions and expansions, during the operation of the solar system.

3. Thermal insulation: Ecological, incombustible and high-density (>50kg/m³) expanded polyurethane surrounds the water storage tank and jacket for minimum heat loss, maintaining the hot water temperature, thickness 50mm.

4. External casing: Hot dip galvanized steel, powder coated RAL9006 / marine grade aluminum alloy.

5. Side flange: Wide opening for easy cleaning of minerals, inspection of the tank and maintenance.

6. Flange sealing: The flange is sealed with a silicon sealant with high heat resistance.

7. Cathode protection: 2 Magnesium anode rods for protection against corrosion and mineral deposits caused by electrolytic reactions.

8. Heating element: Rated according to the destination country’s local regulations (optional, for the use of electricity as an auxiliary power source).

9. Safety thermostat (optional standard only in case that electric heating element is present): With bipolar protection and auxiliary fuse. All electrical components carry a CE marking according to EN 60335-1 and EN 660335-2-21 standards.

10. Protective cover: Protection of the electrical part.

11. Cable gland and cable tube: Water resistant passage for the electric element’s electric connections.

12. Cold Water inlet: Inox BSP male threaded pipe end (3/4” for 300 and 1/2” for rest). At this connection a 9 bar safety non return valve must be placed for pressure relief.

13. Hot Water (DHW) outlet: Inox BSP male threaded pipe end (3/4” for 250, 300 & 500lt tank and 1/2” for 200).

14. Jacket inlet: 3/4" BSP male threaded pipe end. A tee fitting is attached which also provides the filling point for the closed circuit, which must be plugged after filling is done.

15. Jacket outlet: 3/4" BSP male threaded pipe end.

16. 2.5 bar safety valve connection point: Inox 1/2" BSP male threaded pipe end.

17. Heat exchanger coil: Optional part, with ¾” BSP male threaded ends for use with conventional heating systems.

.jpg)